The example shown above is known as the single predetermined overhead rate or plant-wide overhead rate. Different businesses have different ways of costing; some would use the single rate, others the multiple rates, while the rest may make use of activity-based costing. This forecast is called applied manufacturing https://www.bookstime.com/ overhead, a fixed overhead expense applied to a cost object like a product line or manufacturing process. Applied overhead usually differs from actual manufacturing overhead or the actual expenses incurred during production.

Do you already work with a financial advisor?

Now, let’s look at some hypothetical business https://www.facebook.com/BooksTimeInc/ models to see actual use-cases for predetermined overhead rates. During that same month, the company logs 30,000 machine hours to produce their goods. Overhead expenses are generally fixed costs, meaning they’re incurred whether or not a factory produces a single item or a retail store sells a single product. Fixed costs would include building or office space rent, utilities, insurance, supplies, and maintenance and repair.

Monitoring relative expenses

- A pre-determined overhead rate is normally the term when using a single, plant-wide base to calculate and apply overhead.

- Manufacturing overhead is referred to as indirect costs because it’s hard to trace them to the product.

- For example, the costs of heating and cooling a factory in Illinois will be highest in the winter and summer months and lowest in the spring and fall.

- In order to calculate the predetermined overhead rate for the coming period, the total manufacturing costs of $400,000 is divided by the estimated 20,000 direct labor hours.

- Once you have a handle on your estimated overhead costs, you can plug these numbers into the formula.

- Our timesheet feature is a secure way to track the cost and the time your team is putting into completing their tasks.

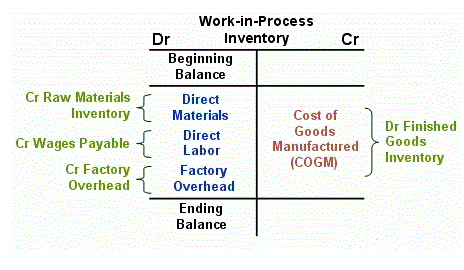

MRP software also tracks demand forecasting, equipment maintenance scheduling, job costing, and shop floor control, among its many other functionalities. Yes, it’s a good idea to have predetermined overhead rates for each area of your business. Again, this predetermined overhead rate can also be used to help the business owner estimate their margin on a product. To calculate your allocated manufacturing overhead, start by determining the allocation base, which works like a unit of measurement. At the end of the accounting period the applied overhead is compared to the actual overhead and any difference is posted to the cost of goods sold or, if significant, to work in process. The activity base for applying manufacturing overhead is normally a unit quantity which relates to the manufacturing process such as the following.

- First, identify the manufacturing expenses in your business for a given period.

- Overhead costs are then allocated to production according to the use of that activity, such as the number of machine setups needed.

- This option is best if you’re just starting out and don’t have any historical data to work with.

- That is, the company is now aware that a 5-hour job, for instance, will have an estimated overhead cost of $100.

- For example, we can use labor hours worked, and for calculating overhead for the store department, we can use the quantity of material to be used.

Variable Overhead Costs

By using the predetermined rate product costs and therefore selling prices can be calculated quickly throughout the year without the need to wait for actual overheads to be determined and allocated. In addition while manufacturing overheads might vary seasonally throughout the year, the use of a constant predetermined rate avoids a similar variation in unit product cost. If a job in work in process has recorded actual labor costs of 6,000 for the accounting period then the predetermined overhead applied to the job is calculated as follows. To calculate a predetermined overhead rate, divide the manufacturing overhead cost by the units of allocation. This is related to an activity rate which is a similar calculation used in Activity-based costing. A pre-determined overhead rate is normally the term when using a single, plant-wide base to calculate and apply overhead.

Applied Manufacturing Overhead

Finally, using a predetermined overhead rate can result in inaccurate decision-making if the rate is significantly different from the actual overhead cost. Calculating your monthly or yearly manufacturing overhead can help you improve your company’s financial plan and find ways to budget for such expenses. Companies with effective strategies to calculate and plan for manufacturing overhead costs tend to be more prepared for business emergencies than businesses that never consider overhead expenses.

- A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs.

- The estimate is made at the beginning of an accounting period, before the commencement of any projects or specific jobs for which the rate is needed.

- By having multiple rates like this, you can achieve a greater degree of accuracy.

- The estimate will be made at the beginning of an accounting period, before any work has actually taken place.

- However, it is included in the Cost of Goods Sold (COGS) section on the income statement, which covers all production costs, including overhead.

Manufacturing overhead is the sum of all the manufacturing costs except direct labor or direct materials costs. The estimated manufacturing predetermined manufacturing overhead rate formula overhead cost applied to the job during the accounting period will be 1,450. The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,600.